Thermal Runaway occurs most often in a valve regulated acid (VRLA) battery when the rate of internal heat generation exceeds the rate at which the heat can be expelled. If this condition continues for an extended period, the VRLA battery temperature will increase until the cells dry out and the container softens, breaks and melts.

Thermal Runaway occurs most often in a valve regulated acid (VRLA) battery when the rate of internal heat generation exceeds the rate at which the heat can be expelled. If this condition continues for an extended period, the VRLA battery temperature will increase until the cells dry out and the container softens, breaks and melts.

If your VRLA battery experiences thermal runaway, the heat it generates will destroy it. While inconvenient, and expensive, thermal runaway and the destruction it causes can also be dangerous. The chemicals that are released during thermal runaway can be toxic and in extreme cases, thermal runaway can cause electrical fires and/or batteries to explode.

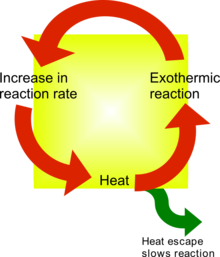

There are two factors involved in the creation of thermal runaway: heat and charge current. Batteries connected to a charger must be temperature controlled and charging voltage and current must be properly limited. Once thermal runaway begins to occur, it cannot stop itself. The battery will heat up a bit which lowers the internal resistance to the charging current and permits more current, creating more heat… thus the term, runaway. The only way to stop it is to remove the batteries from the facility, install a new battery, and properly dispose of the faulty battery.

It is important to understand thermal runaway and its prevention however, it would be unusual to experience thermal runaway in a properly installed, maintained and applied VRLA battery system.

Regular preventative maintenance can spot problematic batteries or cells before they fail and can also allow technicians to adjust charging voltage and current to ensure the batteries are not overcharged. The ambient air temperature in the battery environment must also be properly maintained. Controlling these factors reduces the potential for thermal runaway.

If your batteries are aging, replacement VRLA batteries may be necessary. Newer batteries are less likely to develop a problem; the EnerSys HX205 and HX505 are two of the most reliable.

If in doubt, request a free site survey from a reliable company. It’s best to take some time to get your questions answered now than to have problems arise later. During a site survey, the technician will likely note the capacity of the battery charging device, record the make, model, discharge, and recharge specifications of the battery, and record the cooling capacity of the room air handling equipment. Finally, the technician will discuss critical load demands and possible future demands or changes the battery may be asked to support.